04 Aug 2022

How a water softener works?

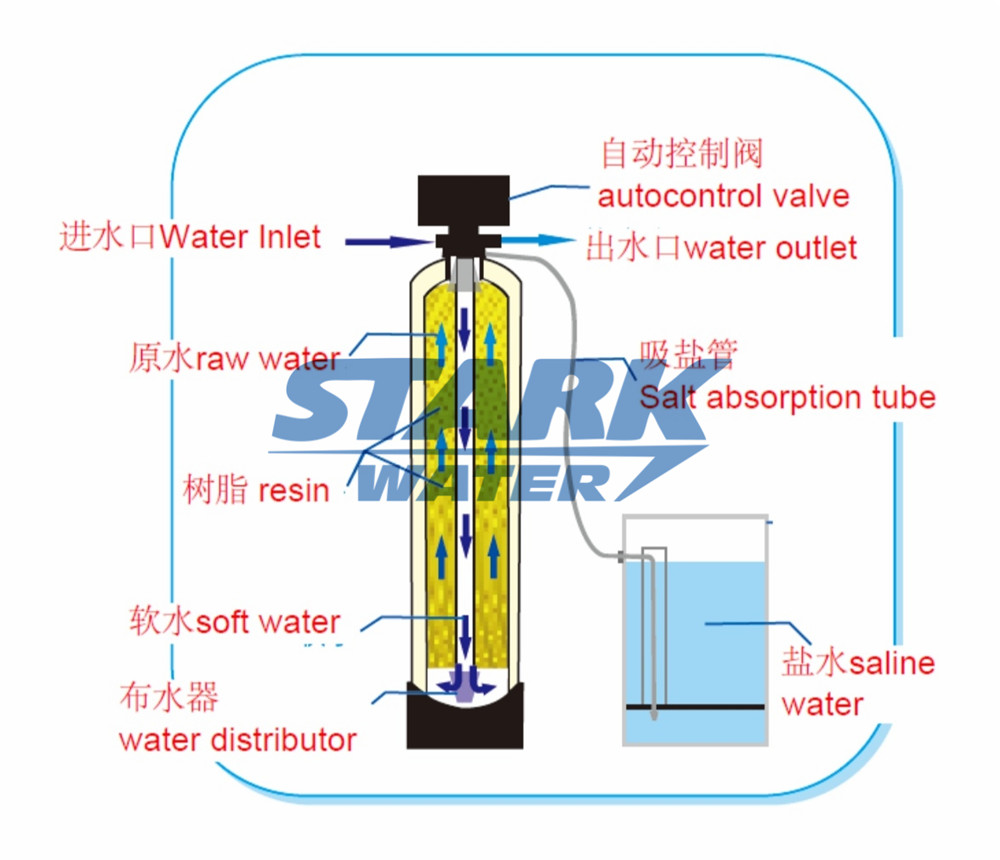

1. Working principle

The hydraulic control valve uses the kinetic energy of the water flow to drive two sets of turbines to drive two sets of gears to drive the rotation of the water dial and the control panel. The accumulated flow of the water dial, the control panel introduces the raw water pressure signal into a set of valve chambers through a set of orifices, and opens or closes the pressure orifices according to the set rule while rotating, so as to realize the automatic switching of an integrated set of valves .

QC-RST series water softener consists of two resin tanks (main tank and auxiliary tank) hydraulic control valve and salt tank. The control valve controls the water circuit to switch between the main tank and the auxiliary tank to ensure that there is always a tank in working condition , while the other tank is in the regeneration or standby state, the regeneration brine is sucked by the negative pressure of the Venturi injector installed in the valve, and the regeneration and cleaning water is the softened effluent of the other tank. Different numbers of water dials are used for different raw water hardness to achieve corresponding working and regeneration cycles.

The hardness of water is mainly composed of cations: calcium (Ca2+), magnesium (Mg2+) ions. When the raw water with hardness passes through the resin layer of the exchanger, the calcium and magnesium ions in the water are adsorbed by the resin, and sodium ions are released at the same time, so the water flowing out of the exchanger is softened water with the hardness ions removed. After the magnesium ion reaches a certain saturation, the hardness of the effluent increases. At this time, the water softener will automatically regenerate the failed resin according to the predetermined program, and use a higher concentration of sodium chloride solution (salt water) to pass through the resin to make the failed resin. The resin reverted back to the sodium form.

Usually the main components of the water softener are: resin tank, resin, control valve, and salt-dissolving tank. The control valve determines the working mode of the water softener. Generally, there are two working modes: manual and automatic. The automatic working mode of the water softener is used in water treatment. Industry has a wide range of applications

2.Working process of automatic water softener

The automatic water softener generally adopts fixed-bed downstream regeneration, and the working process is operation, backwashing, regeneration, replacement, positive washing, and salt tank water injection.

1. Running, also known as producing soft water

Under a certain pressure and flow, the raw water enters the resin tank equipped with sodium ion exchange resin, and the exchangeable ion Na+ contained in the resin undergoes ion exchange softening reaction with Ca2+ and Mg2+ in the water, so that the hardness of the effluent meets the requirements for use.

When the water hardness exceeds the usage requirements, the water softener will start the regeneration program according to the time or flow signal, and each step of the regeneration cycle will be automatically completed by the regeneration controller according to the set time.

2. Backwash (the first step of regeneration cycle)

After the resin fails, backwash with water from bottom to top before resin regeneration. There are two purposes of backwashing. One is to loosen the compressed resin layer during operation through backwashing, which is conducive to resin particles and regeneration The liquid is fully contacted, and the second is to remove the suspended solids accumulated on the resin surface during operation, and some broken resin particles can also be discharged with the backwash water. In this way, the water flow resistance of the water softener will not increase. In order to ensure that the complete resin will not be washed away during backwashing, when designing the water softener, a certain backwashing space should be left on the resin layer. The greater the backwash strength, the larger the required backwash space. Usually, 50% of the resin layer height is selected as the backwash expansion height. The backwash flow rate it adapts to is 12m/h. regeneration effect.

3. Regeneration, also known as salt absorption (second step of regeneration cycle)

Saturated salt solution is sucked from the salt tank and diluted to a specified concentration, and then flows through the failed resin layer at a certain flow rate to reduce the resin to sodium form to restore its softening ability.

4. Replacement, also known as slow washing (the third step of the regeneration cycle)

After the regeneration liquid is fed, there is salt solution that has not yet participated in regeneration and exchange in the expansion space and resin layer of the water softener. Mix clean water with regeneration fluid. Generally, the amount of cleaning water is 0.5-1 times the volume of the resin.

5. Positive washing (the fourth step of regeneration cycle)

In order to remove the residual regeneration waste liquid in the resin layer, it is usually cleaned at the backwash flow rate until the effluent is qualified, and the water flow direction is opposite to that of the backwash.

6. Fill the salt tank with water (the fifth step of the regeneration cycle)

Fill the salt tank with water to dissolve the salt consumption required for the next regeneration. Usually 1 cubic meter of water dissolves 360kg of table salt (concentration is 26.47%), that is, 1 gallon of water dissolves 3 pounds of table salt.

In order to ensure that the concentration of salt solution in the salt tank is saturated, first of all, it should be ensured that the salt dissolution time is not less than 6 hours, and secondly, there must be solid particles of salt in the salt tank.

The above 2-6 is a regeneration cycle program. After the positive washing is completed, that is, when the water injection work of the salt tank starts, the water softener has been transferred to the running state, that is to say, the water injection work of the salt tank and the operation process are carried out at the same time. Until the water filling of the salt tank is completed.

If the fixed bed countercurrent regeneration is used, the working process is: operation, regeneration, replacement, backwashing, and positive washing.

Because the automatic water softener adopts countercurrent regeneration without top pressure, it is necessary to control the regeneration flow rate to prevent the resin from turbulent layers. Generally, the regeneration flow rate is required to be less than 2m/h, otherwise the effect of countercurrent regeneration will be greatly affected.

We must cherish every drop of water, not cherish water and waste water, the last drop of water may be human tears

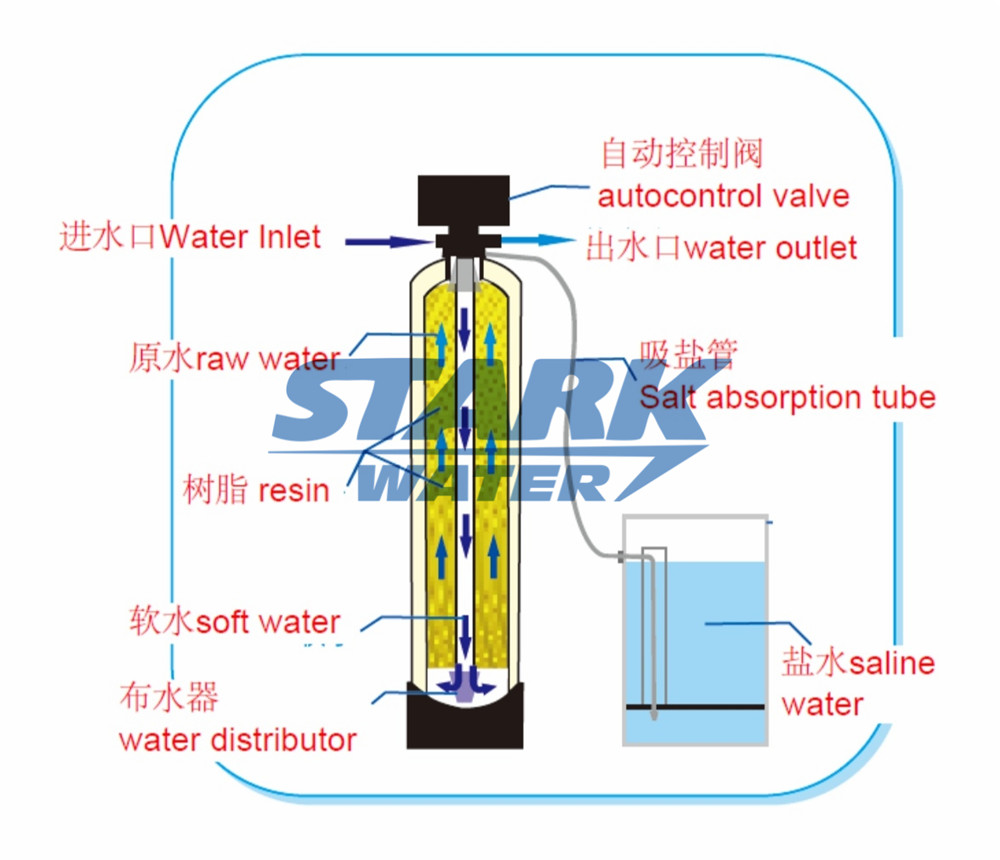

The hydraulic control valve uses the kinetic energy of the water flow to drive two sets of turbines to drive two sets of gears to drive the rotation of the water dial and the control panel. The accumulated flow of the water dial, the control panel introduces the raw water pressure signal into a set of valve chambers through a set of orifices, and opens or closes the pressure orifices according to the set rule while rotating, so as to realize the automatic switching of an integrated set of valves .

QC-RST series water softener consists of two resin tanks (main tank and auxiliary tank) hydraulic control valve and salt tank. The control valve controls the water circuit to switch between the main tank and the auxiliary tank to ensure that there is always a tank in working condition , while the other tank is in the regeneration or standby state, the regeneration brine is sucked by the negative pressure of the Venturi injector installed in the valve, and the regeneration and cleaning water is the softened effluent of the other tank. Different numbers of water dials are used for different raw water hardness to achieve corresponding working and regeneration cycles.

The hardness of water is mainly composed of cations: calcium (Ca2+), magnesium (Mg2+) ions. When the raw water with hardness passes through the resin layer of the exchanger, the calcium and magnesium ions in the water are adsorbed by the resin, and sodium ions are released at the same time, so the water flowing out of the exchanger is softened water with the hardness ions removed. After the magnesium ion reaches a certain saturation, the hardness of the effluent increases. At this time, the water softener will automatically regenerate the failed resin according to the predetermined program, and use a higher concentration of sodium chloride solution (salt water) to pass through the resin to make the failed resin. The resin reverted back to the sodium form.

Usually the main components of the water softener are: resin tank, resin, control valve, and salt-dissolving tank. The control valve determines the working mode of the water softener. Generally, there are two working modes: manual and automatic. The automatic working mode of the water softener is used in water treatment. Industry has a wide range of applications

2.Working process of automatic water softener

The automatic water softener generally adopts fixed-bed downstream regeneration, and the working process is operation, backwashing, regeneration, replacement, positive washing, and salt tank water injection.

1. Running, also known as producing soft water

Under a certain pressure and flow, the raw water enters the resin tank equipped with sodium ion exchange resin, and the exchangeable ion Na+ contained in the resin undergoes ion exchange softening reaction with Ca2+ and Mg2+ in the water, so that the hardness of the effluent meets the requirements for use.

When the water hardness exceeds the usage requirements, the water softener will start the regeneration program according to the time or flow signal, and each step of the regeneration cycle will be automatically completed by the regeneration controller according to the set time.

2. Backwash (the first step of regeneration cycle)

After the resin fails, backwash with water from bottom to top before resin regeneration. There are two purposes of backwashing. One is to loosen the compressed resin layer during operation through backwashing, which is conducive to resin particles and regeneration The liquid is fully contacted, and the second is to remove the suspended solids accumulated on the resin surface during operation, and some broken resin particles can also be discharged with the backwash water. In this way, the water flow resistance of the water softener will not increase. In order to ensure that the complete resin will not be washed away during backwashing, when designing the water softener, a certain backwashing space should be left on the resin layer. The greater the backwash strength, the larger the required backwash space. Usually, 50% of the resin layer height is selected as the backwash expansion height. The backwash flow rate it adapts to is 12m/h. regeneration effect.

3. Regeneration, also known as salt absorption (second step of regeneration cycle)

Saturated salt solution is sucked from the salt tank and diluted to a specified concentration, and then flows through the failed resin layer at a certain flow rate to reduce the resin to sodium form to restore its softening ability.

4. Replacement, also known as slow washing (the third step of the regeneration cycle)

After the regeneration liquid is fed, there is salt solution that has not yet participated in regeneration and exchange in the expansion space and resin layer of the water softener. Mix clean water with regeneration fluid. Generally, the amount of cleaning water is 0.5-1 times the volume of the resin.

5. Positive washing (the fourth step of regeneration cycle)

In order to remove the residual regeneration waste liquid in the resin layer, it is usually cleaned at the backwash flow rate until the effluent is qualified, and the water flow direction is opposite to that of the backwash.

6. Fill the salt tank with water (the fifth step of the regeneration cycle)

Fill the salt tank with water to dissolve the salt consumption required for the next regeneration. Usually 1 cubic meter of water dissolves 360kg of table salt (concentration is 26.47%), that is, 1 gallon of water dissolves 3 pounds of table salt.

In order to ensure that the concentration of salt solution in the salt tank is saturated, first of all, it should be ensured that the salt dissolution time is not less than 6 hours, and secondly, there must be solid particles of salt in the salt tank.

The above 2-6 is a regeneration cycle program. After the positive washing is completed, that is, when the water injection work of the salt tank starts, the water softener has been transferred to the running state, that is to say, the water injection work of the salt tank and the operation process are carried out at the same time. Until the water filling of the salt tank is completed.

If the fixed bed countercurrent regeneration is used, the working process is: operation, regeneration, replacement, backwashing, and positive washing.

Because the automatic water softener adopts countercurrent regeneration without top pressure, it is necessary to control the regeneration flow rate to prevent the resin from turbulent layers. Generally, the regeneration flow rate is required to be less than 2m/h, otherwise the effect of countercurrent regeneration will be greatly affected.

We must cherish every drop of water, not cherish water and waste water, the last drop of water may be human tears