STARK Stainless Steel RO Membrane Housing 8040 RO pressure Vessels

STARK Stainless Steel RO Membrane Housing 8040 RO pressure VesselsSTARK Stainless Steel RO Membrane Housing 8040 RO pressure Vessels

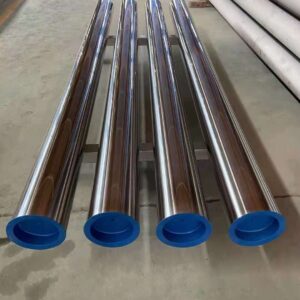

Protect your RO membranes and ensure peak performance with Stark Water’s Stainless Steel RO Membrane Housing. Designed for 8040 RO elements, these robust RO pressure vessels provide secure, leak-proof containment crucial for industrial reverse osmosis systems, ensuring efficient and reliable water purification.

Product Description

At the core of any high-performing Reverse Osmosis (RO) system lies the membrane housing, a critical component responsible for safely containing the RO membranes under high pressure. The Stark Water Stainless Steel RO Membrane Housing (8040) is meticulously engineered to provide superior protection and optimal performance for your industrial RO systems. This robust **RO pressure vessel** is designed for reliability, longevity, and seamless integration, safeguarding your most valuable purification assets.

Engineered for 8040 RO Membranes

This **membrane housing** is specifically designed to perfectly accommodate standard **8040 RO membranes** (8-inch diameter, 40-inch length), which are widely used in industrial and commercial RO applications. Its precise internal dimensions ensure optimal fit and performance, preventing bypass and maximizing the efficiency of the reverse osmosis process. Whether your system uses a single 8040 membrane or multiple in series, our housing provides the ideal, high-pressure environment for the membranes to effectively separate pure water from contaminants.

Premium Stainless Steel Construction & High-Pressure Resilience

Durability and safety are paramount for pressure vessels. Our RO membrane housing is constructed from high-grade **stainless steel** (typically SUS304 or SUS316L). This material offers exceptional corrosion resistance, crucial for aggressive water chemistries and demanding industrial environments. The robust stainless steel construction enables the housing to safely withstand the high operating pressures (often 200-400 PSI, or even higher for brackish/seawater applications) required for efficient reverse osmosis, providing a secure and reliable containment vessel for your membranes. The inherent strength and integrity of stainless steel ensure a long operational lifespan, minimizing the risk of leaks or catastrophic failures.

Absolutely Sealed Design for Leak-Proof Performance

A key feature of the Stark Water membrane housing is its **absolutely sealed design**. Precision manufacturing, combined with high-quality sealing components (such as O-rings), ensures a leak-proof seal under extreme operating pressures. This critical design element prevents any untreated water from bypassing the RO membranes, guaranteeing that all water flows through the purification process. The result is consistently high-quality permeate and protection against contamination of your purified water stream, safeguarding your final product and downstream processes.

Ease of Maintenance & Long-Term Value

Designed for practical industrial use, this stainless steel membrane housing facilitates relatively easy installation and maintenance. Its robust build and high-quality materials reduce the need for frequent replacements or repairs, contributing to lower long-term operational costs. By protecting the sensitive RO membranes from external damage and ensuring efficient flow, our **membrane housing** extends the lifespan of your entire RO system, providing reliable performance and excellent value over time.

Product Parameter

| Parameter | Specification / Customization Options |

|---|---|

| Core Keyword Focus | Membrane Housing design and capabilities. |

| Compatible Membrane Size | 8040 (8-inch diameter, 40-inch length) RO Membrane Elements. Can accommodate 1 to 6+ elements per vessel. |

| Material Construction | Stainless Steel (SUS304 or SUS316L, specific grade can be chosen based on application and water chemistry). |

| Design Type | End-entry or Side-entry ports. Multi-port options for complex arrays. |

| Max. Operating Pressure | Typically 300 PSI, 450 PSI, 600 PSI, 1000 PSI, 1200 PSI (designed to specific pressure requirements for brackish or seawater RO). |

| Max. Operating Temperature | Up to 49°C (120°F) – depending on sealing materials. |

| Permeate Port Size | Standard 1″ or 1.5″ NPT/BSP. |

| Concentrate/Inlet Port Size | Standard 1.5″ or 2″ NPT/BSP (or larger flanges). |

| End Cap Material | Stainless Steel (compatible with housing material) or high-strength ABS/PVC. |

| Sealing Material | EPDM, Viton (FKM), Buna-N (NBR) O-rings (selected based on chemical compatibility and temperature). |

| Surface Finish | Polished or Pickled/Passivated (internal and external) for enhanced corrosion resistance. |

| Mounting Saddles | Included stainless steel saddles for secure mounting. |

| Testing & Certification | Pressure tested; ASME code stamp available upon request for high-pressure applications. |

Applicable Industry

- Industrial Water Treatment Plants: Serving as the core containment for RO membranes in large-scale systems providing purified water for various industrial processes.

- Food & Beverage Industry: Used in RO systems that produce high-purity process water for beverage production, dairy processing, and food ingredient preparation, ensuring product consistency and safety.

- Pharmaceutical & Medical Industry: Critical for RO systems generating Purified Water (PW), Water for Injection (WFI) pre-treatment, and other high-purity water requirements in accordance with GMP standards.

- Electronics & Semiconductor Manufacturing: Essential for RO systems producing ultra-pure water (UPW) for chip fabrication and component rinsing, where even trace impurities are unacceptable.

- Power Generation: Utilized in RO systems for boiler feed water pre-treatment and cooling tower make-up water, preventing scaling and corrosion in critical equipment.

- Seawater Desalination Plants: High-pressure versions are integral to reverse osmosis systems converting seawater into fresh water for municipal or industrial use.

- Brackish Water Treatment: For purifying groundwater with high mineral content for various commercial and agricultural applications.

- Wastewater Treatment & Reuse: Employed in RO stages of advanced wastewater treatment facilities to produce high-quality effluent for discharge or reuse.

- Chemical Industry: Used in RO systems for purifying water for chemical formulations, dilutions, and process applications, ensuring purity and preventing reactions.

Advantage One

Advantage TWO

Related Products

Related products

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.