STK 3T Odm Sea water purification Best Reverse Osmosis System Chemical Water Treatment Plant

STK 3T Odm Sea water purification Best Reverse Osmosis System Chemical Water Treatment PlantSTK 3T Odm Sea water purification Best Reverse Osmosis System Chemical Water Treatment Plant

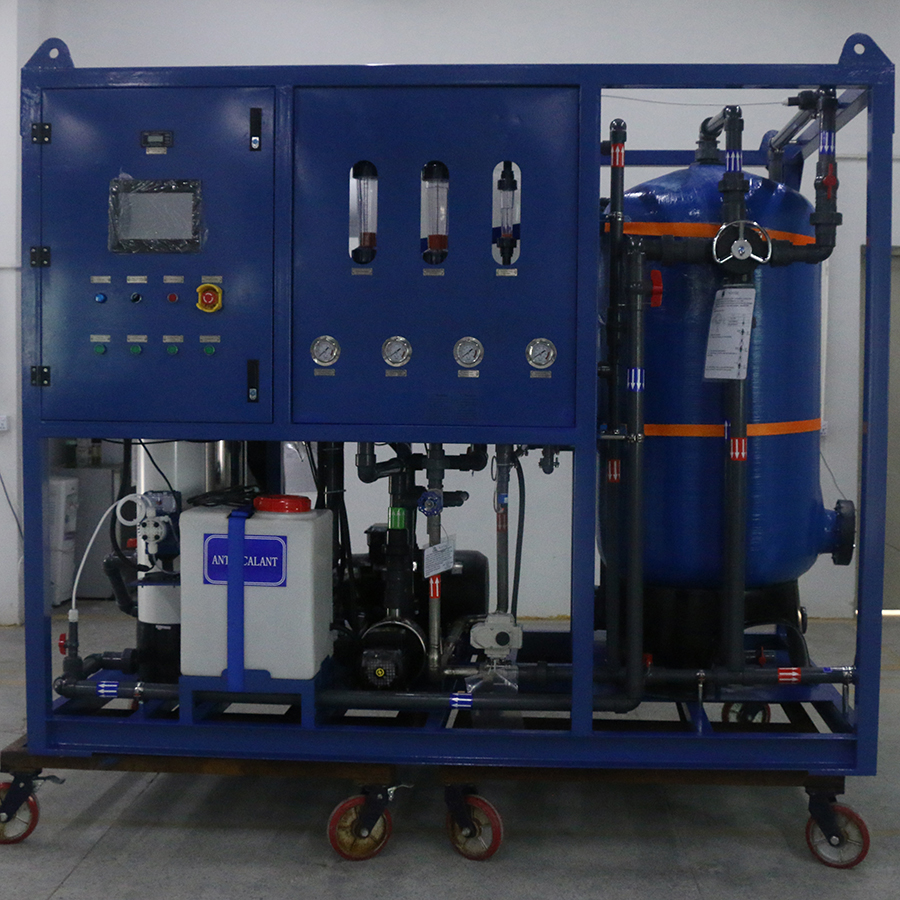

Discover the best reverse osmosis system with Stark Water’s STK 3T ODM Reverse Osmosis Drinking Water System. Designed for robust performance, this efficient reverse osmosis system is ideal for large-scale sea water purification and industrial chemical water treatment plant applications, delivering superior purity and reliability.

Product Description

In today’s global landscape, access to reliable sources of pure water is more critical than ever, especially for large-scale industrial operations and potable water supply from challenging sources like seawater. The STARK STK 3T ODM Best Reverse Osmosis System is engineered to meet these immense demands, offering an unparalleled solution for high-capacity purification, whether for drinking water or complex industrial processes. This is more than just a system; it’s a comprehensive reverse osmosis system designed for ultimate performance and adaptability.

The Pinnacle of Reverse Osmosis System Technology

Our STK 3T system embodies the highest standards of reverse osmosis technology. It employs advanced thin-film composite (TFC) membranes and precision-engineered components to achieve exceptional contaminant rejection rates. This system effectively removes up to 99.5% of dissolved salts, minerals, heavy metals, organic compounds, bacteria, viruses, and other impurities from various raw water sources. The “3T” in its name signifies a substantial capacity, typically referring to 3 tons per hour or 3 m³ per hour (3,000 liters per hour), making it ideal for large-scale production requirements. This high-capacity output ensures a continuous and reliable supply of purified water for even the most demanding applications.

Versatility: From Sea Water Purification to Drinking Water Systems

A key strength of the STARK STK 3T system is its remarkable versatility, particularly its capability for sea water purification. While often used for brackish or municipal water sources, this system can be specifically optimized for desalination, transforming highly saline seawater into fresh, potable water. This makes it an invaluable asset for coastal communities, offshore platforms, and island nations grappling with freshwater scarcity. Moreover, as an ODM (Original Design Manufacturer) product, it offers unparalleled customization. This means the system can be precisely tailored to meet the specific requirements of various feed water qualities, desired product water standards, and unique site conditions, ensuring it functions as the best reverse osmosis system for your exact needs.

When configured as a drinking water system, it ensures that treated water meets or exceeds international potable water standards, providing safe and pleasant-tasting water for large populations. Its robust purification stages can effectively handle a wide range of raw water challenges, ensuring consistent output quality.

Integral to Chemical Water Treatment Plant Operations

The STARK STK 3T RO system is also designed for seamless integration as a core component within a broader chemical water treatment plant. It can serve as the primary purification stage, producing high-quality permeate that can then be further polished by technologies like EDI (Electrodeionization) or mixed-bed ion exchange for ultra-pure applications. Its high efficiency in removing a vast array of contaminants reduces the chemical burden on subsequent treatment stages, contributing to a more economical and environmentally responsible overall plant operation. This makes it an indispensable asset for industries that require both high volume and precise water quality for their manufacturing processes, chemical formulations, or boiler feed applications.

Reliability, Efficiency, and Long-Term Value

Built with durability in mind, the STARK STK 3T reverse osmosis system features robust construction and high-quality components, ensuring a long operational lifespan and minimal downtime. Its automated controls provide real-time monitoring and operational safeguards, simplifying management and ensuring consistent performance. The inherent efficiency of RO technology, coupled with our optimized system design, translates into lower energy consumption and reduced chemical usage compared to traditional methods, offering significant long-term cost savings and an excellent return on investment.

Product Parameter

| Parameter | Specification / Customization Options |

|---|---|

| Core Keyword Focus | Reverse osmosis system design and performance. |

| Pure Water Capacity | 3 m³ per Hour (3,000 Liters Per Hour / approx. 13.2 GPM) – Representing “STK-3T”. Custom capacities available. |

| Raw Water Source Compatibility | Municipal Tap Water, Well Water, Brackish Water (TDS up to 10,000 ppm for standard BWRO), or Seawater (TDS up to 45,000 ppm for SWRO configuration). |

| RO Membrane Type | High-rejection Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series, quantity sized for capacity/TDS). Specifically SWRO membranes for seawater. |

| High-Pressure Pump | Energy-efficient, corrosion-resistant centrifugal or positive displacement pump (e.g., Grundfos, Danfoss, CNP), sized for specific flow and pressure. |

| Pre-treatment System |

|

| Salt Rejection Rate | ≥98% – 99.5% (for BWRO); ≥99.5% – 99.7% (for SWRO) |

| Water Recovery Rate | 50% – 75% (BWRO); 30% – 50% (SWRO) – Dependent on raw water quality and system design. |

| Output Water Quality | TDS <100 ppm (for drinking water/process); significantly lower for high-purity applications after post-treatment. Meets WHO standards for drinking water. |

| Power Supply | 3 Phase, 380V/415V/460V, 50Hz/60Hz (Customizable as per regional standards). |

| Control System | Fully Automatic PLC Control with real-time online conductivity/TDS meter, pressure gauges, flow meters, auto-flush, low/high pressure protection, and fault alarms. |

| Construction Material |

|

| Inlet Water Requirements |

|

| Dimensions (Approximate) | Varies significantly based on customization and capacity (e.g., L 2800mm x W 1100mm x H 1900mm for 3m³/hr). |

| Operating Temperature | 5°C – 45°C. |

| Customization | ODM (Original Design Manufacturer) capabilities for tailored solutions. |

Applicable Industry

- Municipal Drinking Water Supply: Provides large volumes of safe, potable drinking water for towns, cities, or communities, especially in areas with limited freshwater resources or high raw water TDS.

- Coastal Communities & Island Nations: Essential for sea water purification, transforming abundant saline water into a reliable source of fresh drinking and utility water, addressing water scarcity.

- Hotels, Resorts & Large Residential Complexes: Ensures a continuous supply of high-quality drinking water and utility water for guests and residents, enhancing comfort and facility operations.

- Food & Beverage Industry: Used as the primary purification stage for process water in beverage production (bottled water, soft drinks, juices, beer), dairy processing, and food ingredient preparation, ensuring product purity, consistency, and safety.

- Pharmaceutical & Medical Industry (Pre-Treatment): Provides highly purified water for pre-treatment stages to produce Purified Water (PW) or Water for Injection (WFI), crucial for drug manufacturing, laboratories, and medical device reprocessing.

- Electronics & Semiconductor Manufacturing (Pre-Treatment): Produces high-purity water for pre-treatment to generate ultra-pure water (UPW) used in chip fabrication and component rinsing, preventing contamination.

- Power Generation: Utilized for boiler feed water pre-treatment, cooling tower make-up water, and turbine washing in power plants, preventing scaling and corrosion and improving energy efficiency.

- Chemical Industry (Chemical Water Treatment Plant): Serves as a core component in chemical water treatment plants, supplying large volumes of purified water for chemical formulations, dilutions, and various process applications, ensuring product purity and preventing unwanted reactions.

- Agricultural Irrigation (Specific Applications): For large-scale treatment of brackish water for specialized crop irrigation or hydroponics, where specific water quality is critical for plant health and yield.

- Wastewater Treatment & Reuse: Employed in advanced wastewater treatment facilities to produce high-quality effluent suitable for discharge, industrial reuse, or even aquifer recharge.

Advantage One

Advantage TWO

Related Products

Related products

-

Water treatment plant

Marine Reverse Osmosis System 20 m³/d | Shipboard Freshwater | STARK Water

Add to Quote -

Seawater desalination system

STARK Factory competitive price 2000LPH seawater desalination system water treatment filter system

Add to Quote

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.